Chemical Composition

Carbon: 0.42%-0.50%

Manganese: 0.60%-0.90%

Phosphorous: 0.04% (Max)

Sulfur: 0.05% (Max)

Properties

Tensile Strength: 81,900 PSI

Yield Strength: 45,000 PSI

Elongation: 16%

*These numbers are "Typical" properties and may not be required to meet this grade. Please check with your Alro Sales Representative if physical properties are required for your application.

Typical Uses

Typical Uses Include:

- Gears

- Shafts

- Axles

- Rolls

- Studs

- Crankshafts

- Torsion Bars

- Sockets

|

|

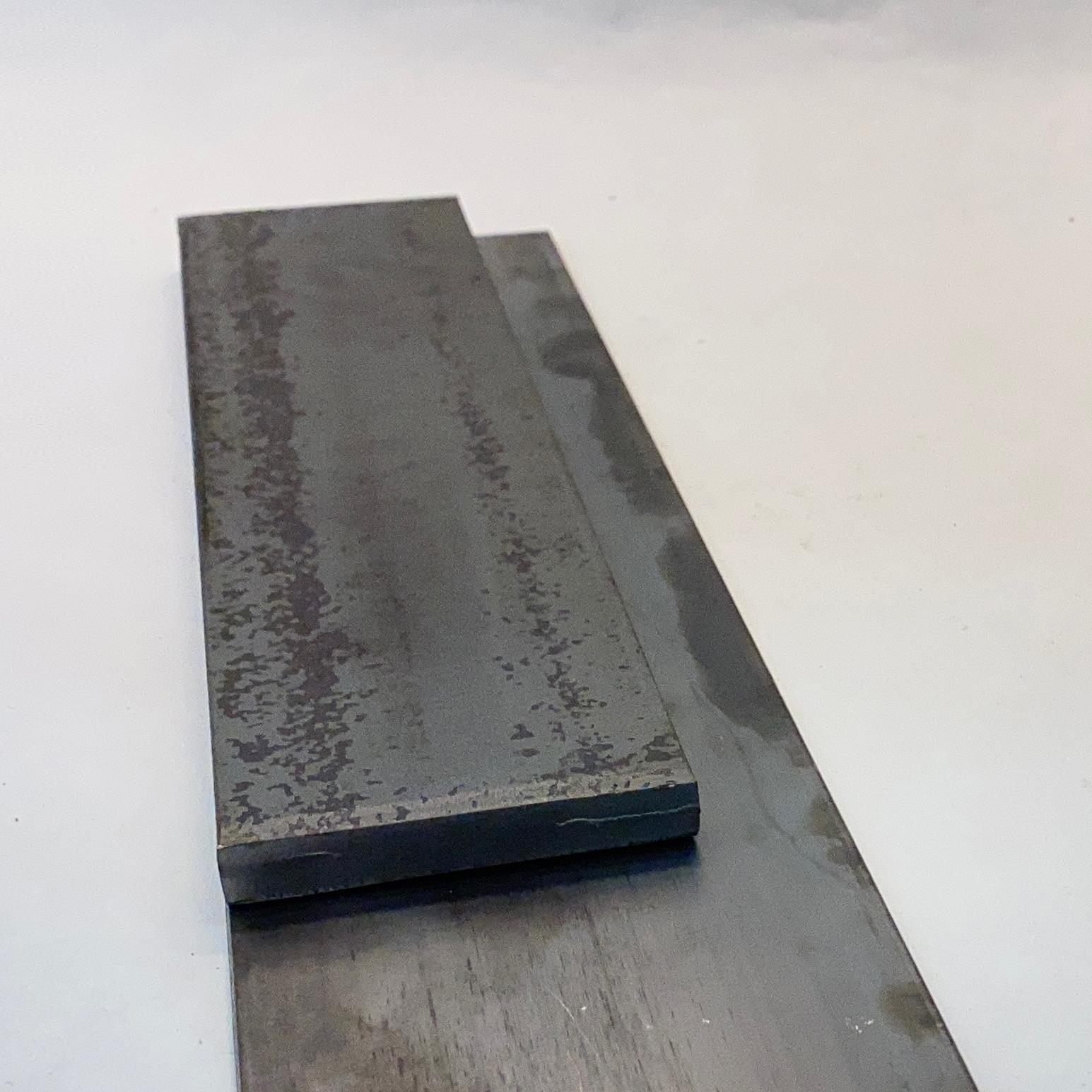

1045 Hot Rolled Plate and 1045 Hot Rolled Bar

Hot Rolled Steel C1045 is a versatile medium tensile strength carbon hot rolled steel bar provides good strength, impact resistance, and provides moderate weldability characteristics. It is a common grade and is selected for applications from bolts, and studs, to axles and crankshafts. It has improved strength over low carbon steels.

Request a quote for further pricing information on 1045 HR steel bar and plate call us at 888-888-2576 and we will gladly answer any questions regarding Hot Rolled Steel C1045 that you may have. Alro Steel is your premier supplier of advanced quality metal products.

C1045 is a tough work hardening steel that is regularly utilized for numerous industrial applications that require steel that is strong and easily managed. Hot Rolled Steel C1045 is silicon killed with a higher carbon content for increased strength. The strength can be improved in the lighter and medium thickness via heat treatment. This steel alloy also provides good machinability, while forming and welding properties are not as profound as other steels. It should be noted that welding is not recommended in the through hardened or flame induction hardened condition.

|

|