Chemical Composition

Carbon: 0.15%-0.2%

Manganese: 0.6%-0.9%

Phosphorus: 0.04% (Max)

Sulfur: 0.05% (Max)

Properties

Physical Properties of 1018 HR Steel in the AS-ROLLED state:

Tensile Strength: 67,000 PSI

Yield Strength: 45,000 PSI

Elongation: 36%

Typical Uses

Typical uses of 1018 HR carbon steel bars include:

Gears

Pinions

Ratchets

Oil tool slips

Pins

Chain pins

Liners

Studs

Anchor pins

|

|

1018 Hot Rolled Carbon Steel Bar

Carbon 1018 hot rolled steel is one of the most commonly available grades available in the world. Despite its unimpressive mechanical properties, this steel alloy is easily formed, machined, welded and fabricated. It is especially suited to cold forming and bending operations. 1018 steel is suitable for parts which require cold forming (such as crimping, swaging, or bending). For severe bends, however, stress relieving may be necessary to prevent cracking.

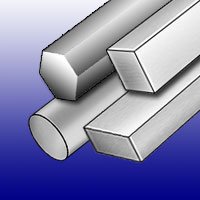

1018 Hot Rolled bars are generally available as round bars, while 1018 Cold Finished bars are available as Flats, Rounds, Squares, and Hexes.

|

|