Chemical Composition

Carbon: 0.15% (Max)

Manganese: 0.60% (Max)

Phosphorus: 0.030% (Max)

Sulphur: 0.035% (Max)

Properties

In general A1008 CR AKDQ is known for:

- Weldability

- Consistency

- Excellent formability / ductility

- Good surface texture

A1008 is typically bought to meet chemistry requirements rather than physical requirements. For that reason, physical properties are generally not provided unless requested prior to production. Any material can be sent to a third party after production to be tested for physical properties.

Typical Uses

A1008 AKDQ is a common choice for automotive stampings including:

• Body sides

• Vehicle Roofs

• Floor pans

• Reinforcements

• Doors

• Deck Lids

• Hoods

|

|

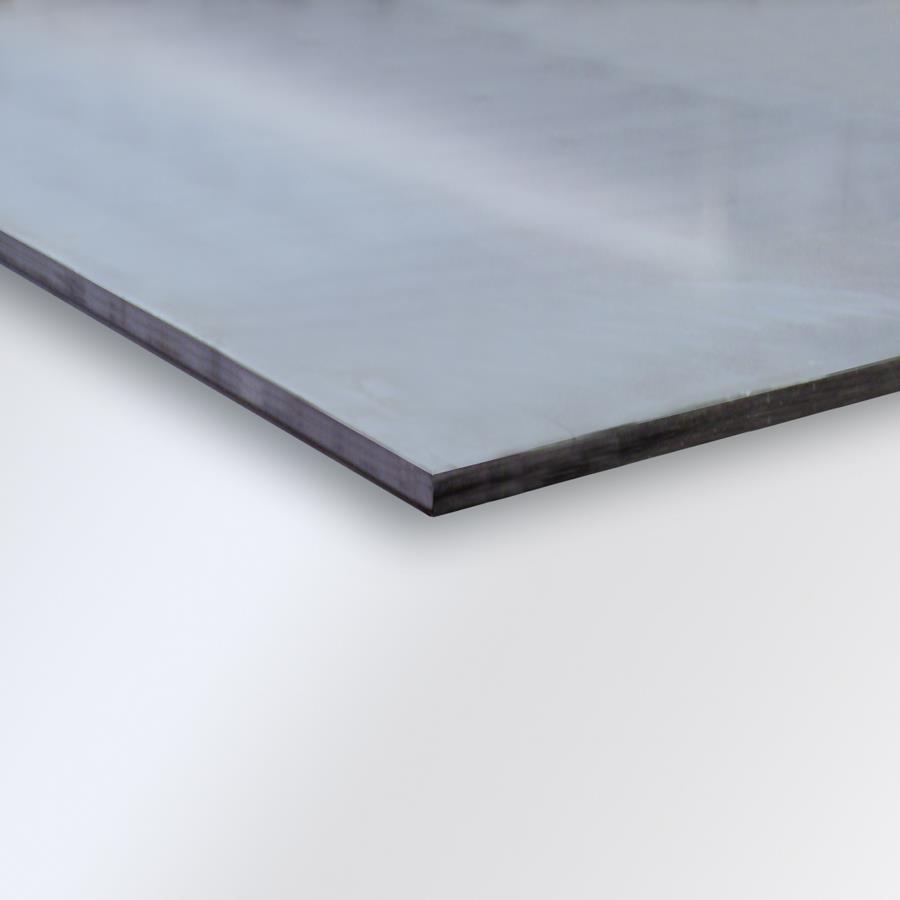

A1008 CR AKDQ - Cold Rolled, Aluminum Killed Drawing Quality

AKDQ stands for Aluminum killed, drawing quality. It refers to the adding aluminum to molten steel during the alloy process followed by the annealing and tempering the sheet undergoes. The benefit of the Aluminum Killed process is uniformity and consistent performance because the addition of aluminum locks up the oxygen, that normally occurs, in the form of aluminum oxide. The end result is an A1008 steel sheet that can be oxy-acetylene or TIG welded with no gas bubbles forming. This product is sometimes referred to as Drawing Steel Type B. A1008 AKDQ is an ideal choice for drawing operations that cannot be performed with A1008 CS Type B.

In addition to A1008 AKDQ, Alro stocks ASTM A1008 CR (Cold Rolled) CS (Commercial Steel) Type B carbon sheet. To learn more about A1008 AKDQ sheet and the other carbon steel materials Alro stocks, contact us today or request a quote.

|

|